Press releases Find out more about intelligent sensors, autonomous actuators and controllers!

Focus on internationalization

Lenord+Bauer focuses on expanding its sales activities by establishing a subsidiary in the USA. As the specialist for installed sensors and integrated drive technology, this move reinforces Lenord+Bauer’s direct contact with customers in the machinery and packaging plant engineering sectors.

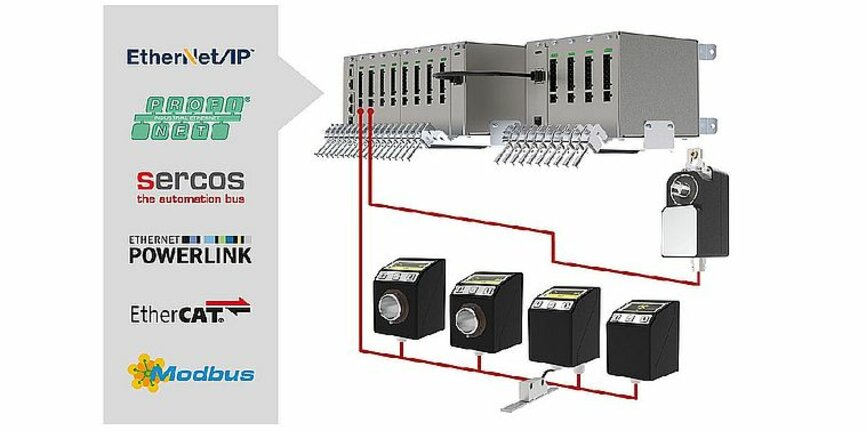

Flexibility due to diverse interfaces

The SeGMo-Assist digital position display for guided, semi-automated format adjustment can now be integrated into control systems with even greater ease. In addition to the CANopen interface, which is integrated in the device, the standard IE fieldbuses are available via the modular SeGMo-Box functioning as a gateway.

"Sensor twins" are the winners

Messtec + sensor masters award 2021: We are happy that we have achieved the second position with our i³SAAC-Precision-System in the category sensor technology.

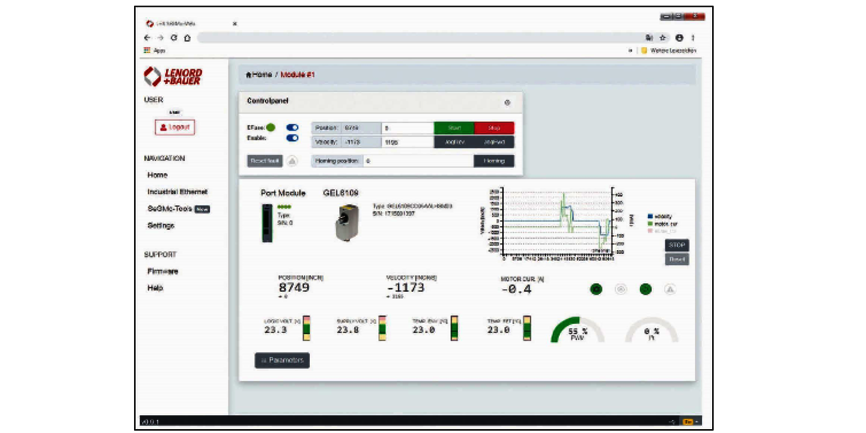

Condition Monitoring: relieving the burden on the PLC

Systems for condition monitoring enable the actual status of the plant to be assessed. To monitor positioning drives, plant manufacturers and operators frequently rely on extensive programming that places unnecessarily high loads on the capacities of the real-time bus. The solution from Lenord+Bauer for data and system analysis provides a remedy.

A direct line to customers

Lenord+Bauer is expanding its sales activities with the establishment of a subsidiary in Italy. As an automation technology specialist, our presence in Milan will reinforce ties with key customers in the mechanical engineering and rail vehicle manufacturing sectors.

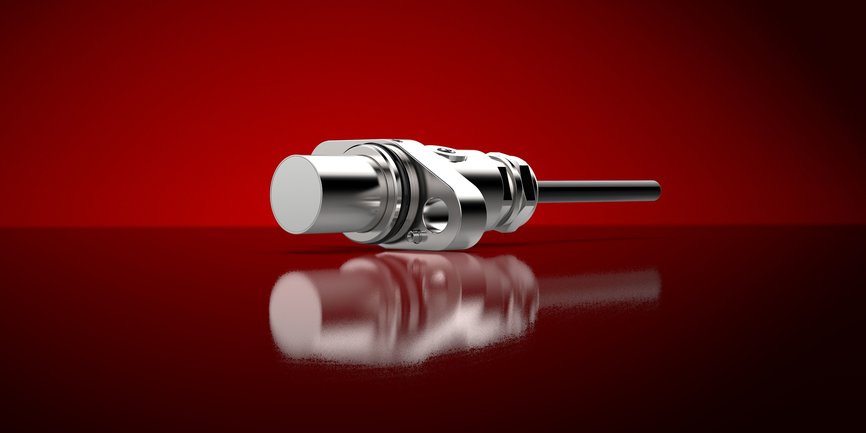

Retrofitting ensures continuous operation

To ensure that modern train control systems receive reliable square-wave signals, vehicle operators have to regularly replace passive sensors with active ones. Lenord+Bauer screw-in threaded sensors are used to upgrade rail vehicles to the state of the art, thus ensuring that they can continue to operate reliably.

The key to process reliability

Fast and controlled format changes: thanks to the intuitive SeGMo-Assist digital position display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment.

Dynamic traction control

When it comes to controlling traction in electric motors, often only slightly resolved speed signals are available. This makes it more difficult to start on inclines, for instance. Thanks to integrated pulse multiplication, a high-resolution speed sensor from Lenord+Bauer enables much more dynamic control behaviour. Rolling detection, too, benefits from the greater number of…

Enjoying work? Of course!

Six Oberhausen companies are among the top employers in the SME sector in 2021. This was a result of a study carried out by news magazine FOCUS Business in cooperation with the ratings platform www.kununu.com.

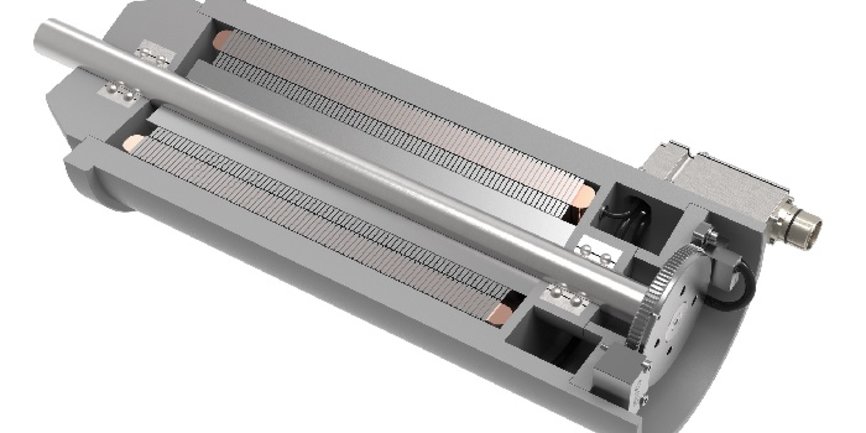

Smart system for positioning applications

In rotary table applications, maximum precision counts when it comes to workpiece positioning. The exact mounting of the target wheel has a considerable influence on the achievable positioning accuracy, especially if the wheel has a small diameter. Thanks to the Precision-System from Lenord+Bauer, this can now be significantly improved. The system also offers advantages for…

Any Questions?

We would be happy to add you to our press mailing list. All you need to do is to send an email!

*Mandatory field

Your contact

Kerstin Frohn, Press Relations Officer

Please send us a courtesy copy or link upon publication. Thank you.