Sensors For heavy-duty applications

Our robust speed sensors, vibration sensors and temperature sensors deliver reliable information about the condition of your system, enabling you to detect malfunctions at an early stage and avoid unplanned downtimes. Alternatively, you can use a CombiCODER to acquire rotational speed, temperature and acceleration in a single pick-up encoder if the installation space is tight.

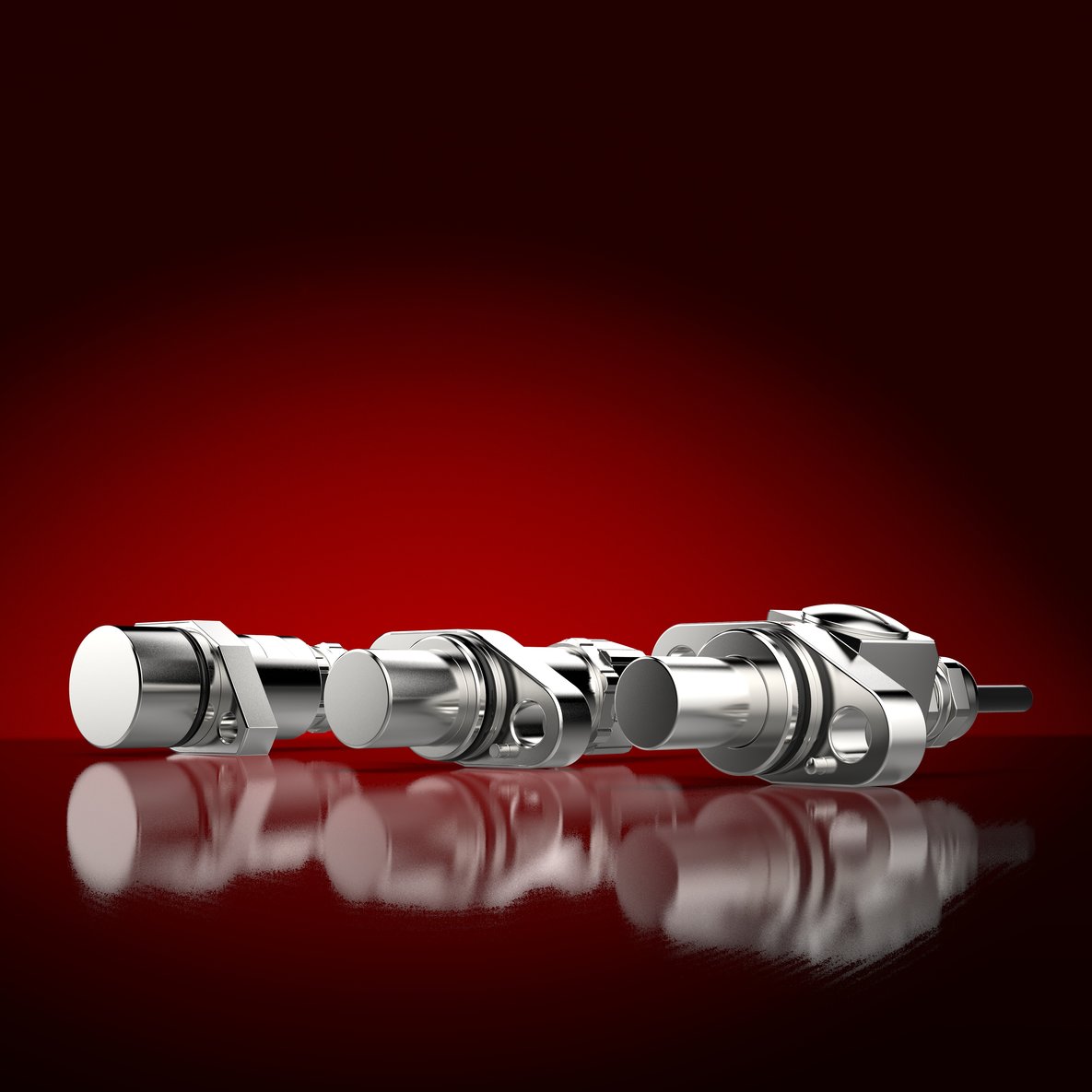

Bearingless speed sensors – Built for the toughest conditions

- Fit, form, and function for over 30 years now

- More than 1 million references

- Project expertise: Qualification, approval, tendering – personal support

Your advantages:

- Reliably detect linear or rotary speed and direction

- Magnetic or inductive – suitable for any metallic measuring scale

- Up to four independent measurement channels in a very compact space

- Maximum efficiency and signal quality

- Customized compact design from the modular system

Temperature sensors – precision meets resilience

- Robust, precise, durable – designed for demanding industrial environments

- Install, connect, trust – for reliable temperature monitoring without any compromises

- Certified quality – to ensure that your systems run securely and reliably at all times

Your advantages:

- Trust in precision: Pt100 / Pt1000 sensors deliver reliable data – anytime, anywhere

- Accurate measured values in every situation: -40 °C to +200 °C

- Fits perfectly into your system: Measuring tube lengths from 30 to 140 mm offer maximum flexibility.

- Simple integration: Variable 2-, 3- or 4-wire circuits

- Certified according to EN 45545 and EN 50155

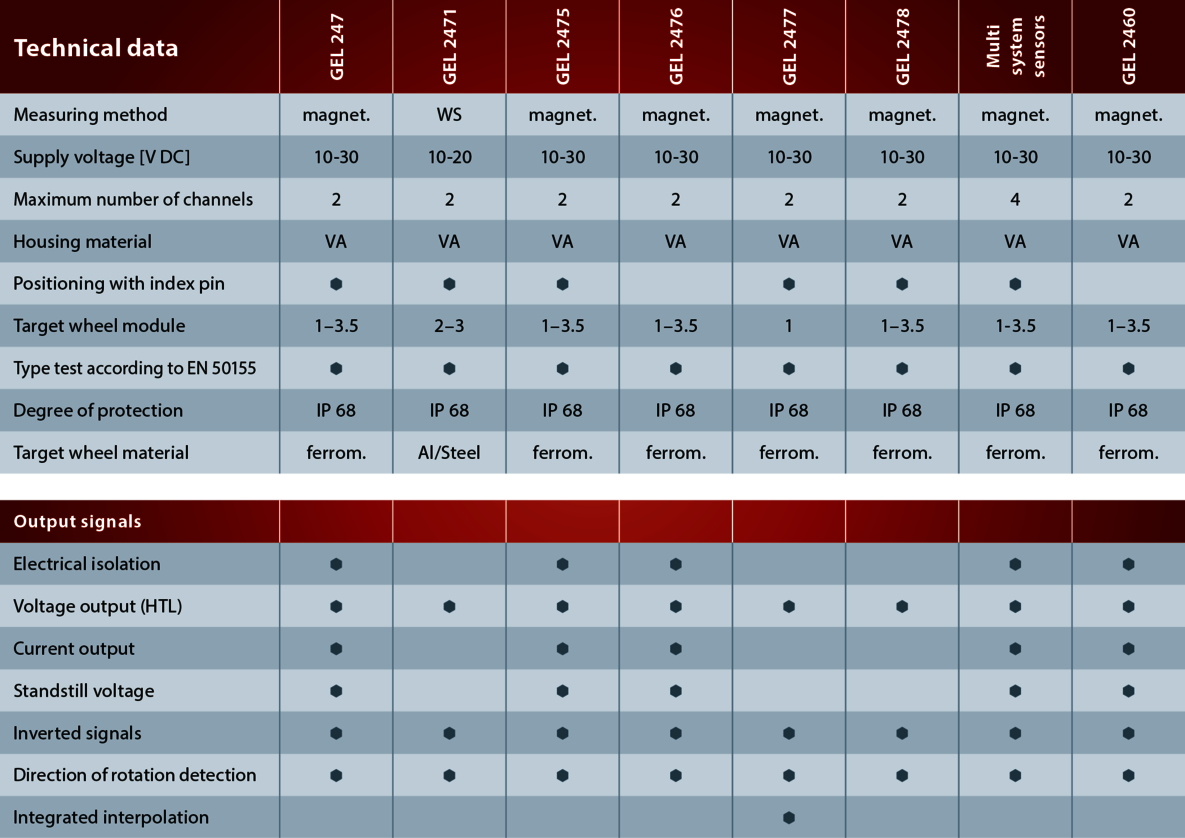

Speed sensors selection guide

WS = eddy current measuring technique; Al = aluminum; VA = stainless steel

Speed sensors and temperature sensors

Individual support

Can’t find a suitable product for your application? We manufacture sensor types in many customer-specific variants. Our technical support team will be happy to advise you. Contact us now!

Your contact

Torsten Kassing, Key Account Manager