Condition Monitoring: relieving the burden on the PLC

Continuous condition monitoring helps to identify imminent failures at an early stage, allowing maintenance operations to be planned and downtimes to be reduced. In the packaging industry this is often realised through time-consuming PLC programming. That not only ties up personnel resources, but also blocks fieldbus capacities. The reaction time of the machine falls because the available bandwidth is utilised for data retrieval. Condition monitoring with the SeGMo system solves these capacity utilisation problems.

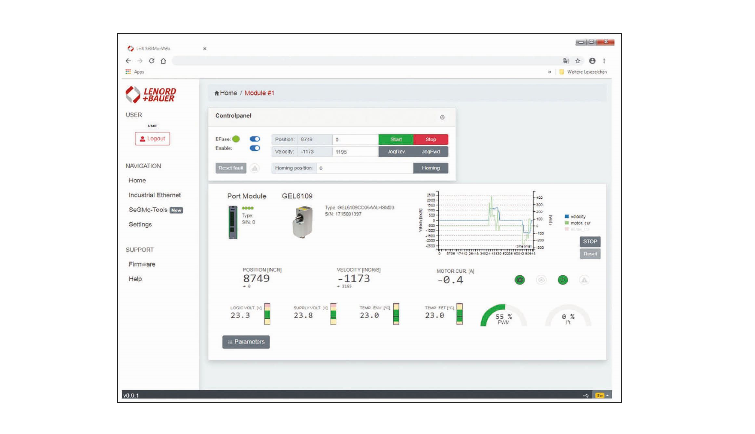

In contrast to approaches where cycles are counted and then compared with the predicted service life, here the positioning drives are kept under permanent monitoring. Independent of any other system, the modular SeGMo-Box enables remote access as a decentral control unit. The user can access the SeGMo system using a web server which optionally provides a separate communication channel that makes the relevant data available independently of the real-time bus. This protects the runtime-critical plant control system against influences from remote accesses and enables a complete overview of the machine in real time.

The user can select the relevant condition data from all the system data held in the web server relating to the positioning drives and have them displayed using the supplied web application. Access to the web application via the browser removes the need to install additional software packages. The dynamically structured web pages adjust automatically to the screen resolution, allowing different terminal devices to be used.

To give a practical example, current data can be compared with past data in the torque analysis. These historic data enable individual applications to be monitored more easily.