Press releases Find out more about intelligent sensors, autonomous actuators and controllers!

Multisystem sensors for signaling upgrades

Lenord+Bauer has developed speed sensors featuring several self-sufficient sensor groups which supply supplementary monitoring devices with independent speed signals without requiring more installation space.

Increased productivity during format changeover

![[Translate to Englisch:] Auszug aus dem Katalog [Translate to Englisch:] Auszug aus dem Katalog](/fileadmin/_processed_/7/d/csm_katalogseiten_c25d4d7605.png)

Lenord+Bauer has published the new solution catalog “Semi- and fully automated format adjustment”. It provides a complete overview of the SeGMo product family, which enables the user to optimize processes, save time and avoid errors.

Innovative through research

Again Lenord, Bauer & Co. GmbH has been awarded the “Innovation through research” seal of the Stifterverband für die deutsche Wissenschaft e.V., a donors' association for the promotion of education, science and innovation in Germany. The award honours the company's commitment to university research, teaching and association work.

Safely avoid motor, gear unit and clutch damage

Lenord+Bauer has developed a space-saving M12 threaded sensor to meet the specific demands of the heavy goods vehicle market. Thanks to an optional standstill signal, it is also suitable for safety applications.

Focus on internationalization

Lenord+Bauer focuses on expanding its sales activities by establishing a subsidiary in the USA. As the specialist for installed sensors and integrated drive technology, this move reinforces Lenord+Bauer’s direct contact with customers in the machinery and packaging plant engineering sectors.

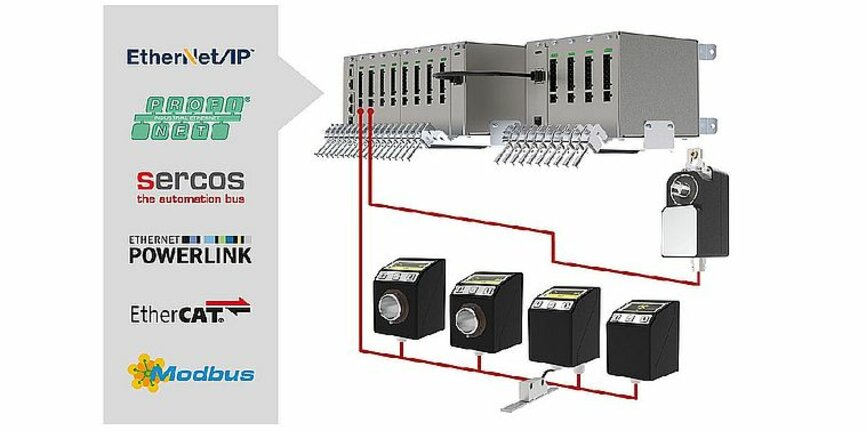

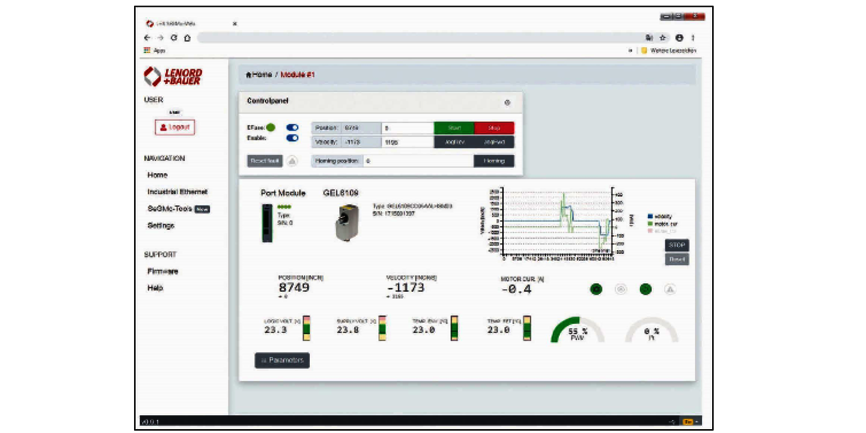

Flexibility due to diverse interfaces

The SeGMo-Assist digital position display for guided, semi-automated format adjustment can now be integrated into control systems with even greater ease. In addition to the CANopen interface, which is integrated in the device, the standard IE fieldbuses are available via the modular SeGMo-Box functioning as a gateway.

"Sensor twins" are the winners

Messtec + sensor masters award 2021: We are happy that we have achieved the second position with our i³SAAC-Precision-System in the category sensor technology.

Condition Monitoring: relieving the burden on the PLC

Systems for condition monitoring enable the actual status of the plant to be assessed. To monitor positioning drives, plant manufacturers and operators frequently rely on extensive programming that places unnecessarily high loads on the capacities of the real-time bus. The solution from Lenord+Bauer for data and system analysis provides a remedy.

A direct line to customers

Lenord+Bauer is expanding its sales activities with the establishment of a subsidiary in Italy. As an automation technology specialist, our presence in Milan will reinforce ties with key customers in the mechanical engineering and rail vehicle manufacturing sectors.

Retrofitting ensures continuous operation

To ensure that modern train control systems receive reliable square-wave signals, vehicle operators have to regularly replace passive sensors with active ones. Lenord+Bauer screw-in threaded sensors are used to upgrade rail vehicles to the state of the art, thus ensuring that they can continue to operate reliably.

Any Questions?

We would be happy to add you to our press mailing list. All you need to do is to send an email!

*Mandatory field

Your contact

Kerstin Frohn, Press Relations Officer

Please send us a courtesy copy or link upon publication. Thank you.