Press releases Find out more about intelligent sensors, autonomous actuators and controllers!

The key to process reliability

Fast and controlled format changes: thanks to the intuitive SeGMo-Assist digital position display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment.

Dynamic traction control

When it comes to controlling traction in electric motors, often only slightly resolved speed signals are available. This makes it more difficult to start on inclines, for instance. Thanks to integrated pulse multiplication, a high-resolution speed sensor from Lenord+Bauer enables much more dynamic control behaviour. Rolling detection, too, benefits from the greater number of…

Enjoying work? Of course!

Six Oberhausen companies are among the top employers in the SME sector in 2021. This was a result of a study carried out by news magazine FOCUS Business in cooperation with the ratings platform www.kununu.com.

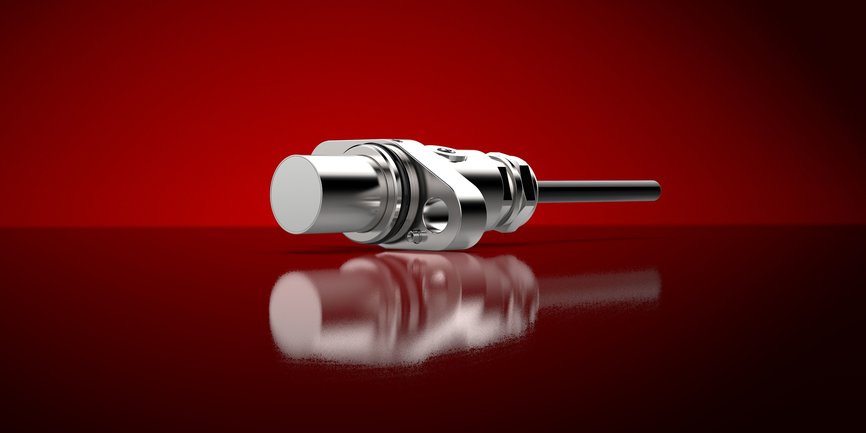

Smart system for positioning applications

In rotary table applications, maximum precision counts when it comes to workpiece positioning. The exact mounting of the target wheel has a considerable influence on the achievable positioning accuracy, especially if the wheel has a small diameter. Thanks to the Precision-System from Lenord+Bauer, this can now be significantly improved. The system also offers advantages for…

Increased route utilisation thanks to Cold Movement Detection

Lenord + Bauer has developed a Cold Movement Detector. This is suitable for all rail vehicles which are to be equipped with an on-board "European Train Control System (ETCS)" including Cold Movement Detection (CMD) according to Baseline 3. Use of the new sensor eliminates the need to travel slowly so that the Radio Block Center (RBC) can determine the position reliably. The…

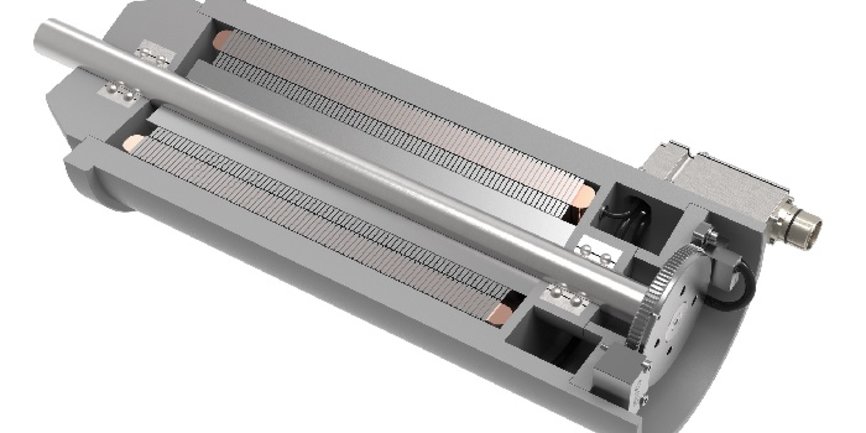

New analysis options in guarantee and service cases

Motor spindles in machine tools are exposed to significant mechanical stresses. Undetected overloading can lead to failures. This can be prevented through predictive maintenance. The i³SAAC MiniCODERs from Lenord+Bauer help in the analysis of spindle data in order to predict the probability of failure. They also enable a fingerprint of the entire sensor system to be taken and…

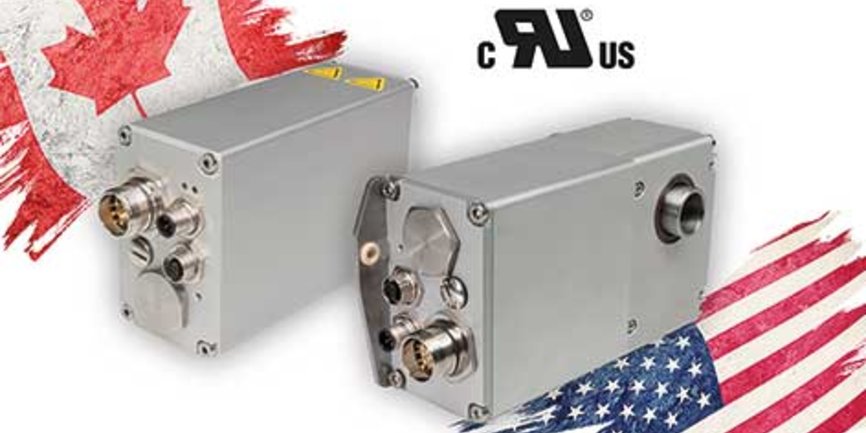

Faster permit procedure in North America

The procedure for obtaining an operating permit for machines and production plants in the USA or Canada is rather like an obstacle course. UL-certified positioning drives from Lenord+Bauer make the machine acceptance process much simpler.

Time saving during vehicle maintenance

The mobile tester from Lenord+Bauer optimises maintenance and servicing work. It can be used to check the operating behaviour of speed sensors with square-wave output signals (current and voltage), irrespective of the provider. Functional capability can be checked not only on sensors that are removed and stored, but also on sensors installed on rotating motors. Testing is…

Simplifying the exchange of information

The umati (universal machine tool interface) network was launched with the aim of driving digital networking forward by means of universal, standardised interfaces. Lenord+Bauer's contribution to the project is intelligent encoder kits that allow process data to be transferred in a uniform language. This delivers new approaches to condition monitoring.

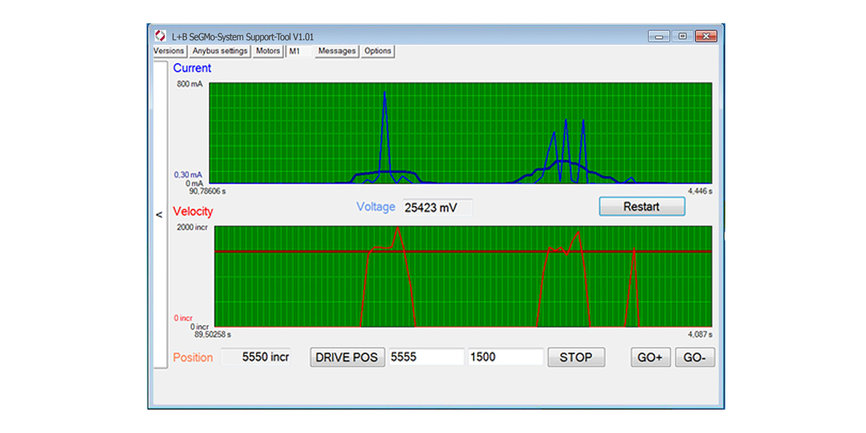

Condition monitoring for positioning drives

Lenord+Bauer supports Industry 4.0 applications. The specialist in motion sensors and integrated drive technology expands the product range by a decentral control unit that allows the remote access to positioning drives. This opens up new possibilities for condition monitoring.

Any Questions?

We would be happy to add you to our press mailing list. All you need to do is to send an email!

*Mandatory field

Your contact

Kerstin Frohn, Press Relations Officer

Please send us a courtesy copy or link upon publication. Thank you.