Condition monitoring for positioning drives

Modern and efficient operating concepts that identify trends in the machine data and report them to a service body are increasingly in demand. Statistical analysis of the data allows recurring critical conditions to be detected at an early stage, enhancing the efficiency of the converting line through targeted interventions.

The SeGMo-System from Lenord+Bauer allows the option of active condition monitoring. It consists of three individual elements that can be flexibly combined as required: positioning drives by the name of SeGMo, the decentralised SeGMo-Box control unit for flexible fieldbus integration and the associated hybrid cable solution, including connectors, that is suitable for use with drag chains.

The modular SeGMo-Box allows up to 17 secondary axes to be automated with intelligent positioning drives. A maximum of four boxes can be combined into a logical unit. At the heart of the modular control unit is the CPU module in the master box. What are known as COM modules ensure communication between the individual boxes with four or nine selectable module slots.

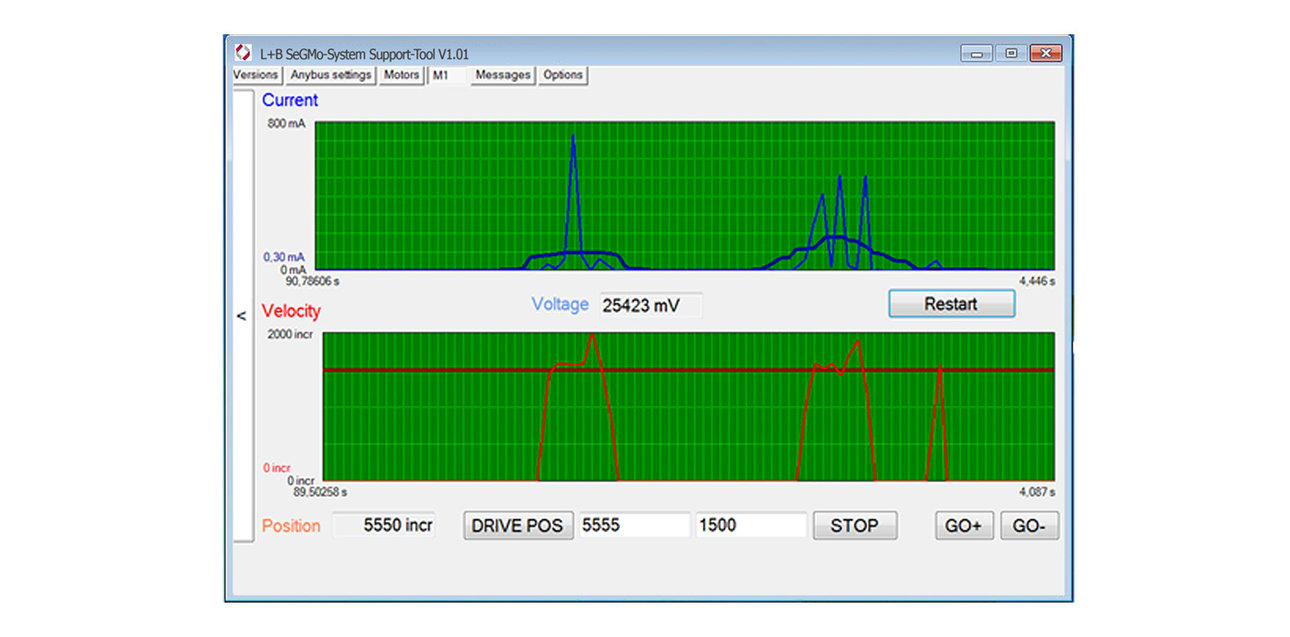

The SeGMo-Positioning internally monitor data such as motor current, speed and temperature. In the event of an error, the positioning drives output alarms and messages and alert the operating personnel.

The real-time-capable communication and exchange of data between sub-systems are just one step towards full digitalisation. Information on the condition of machines and their components plays a key role in the complete production process.

In addition to monitoring through the PLC, the user can access the SeGMo-System remotely using a web server. The system provides a separate communication channel through which the machine operator receive the relevant data independently of the real-time bus. That allows to protect the runtime-critical plant control system against influences from remote accesses and gives a complete overview of the machine.

The integrated absolute multiturn encoder means the drive is aware of its current position at all times. These limits are not exceeded even if the user makes an incorrect input, protecting the machine from critical situations.