Efficient adjustment of feed axes New in the SeGMo product range

Maximum success with minimum effort

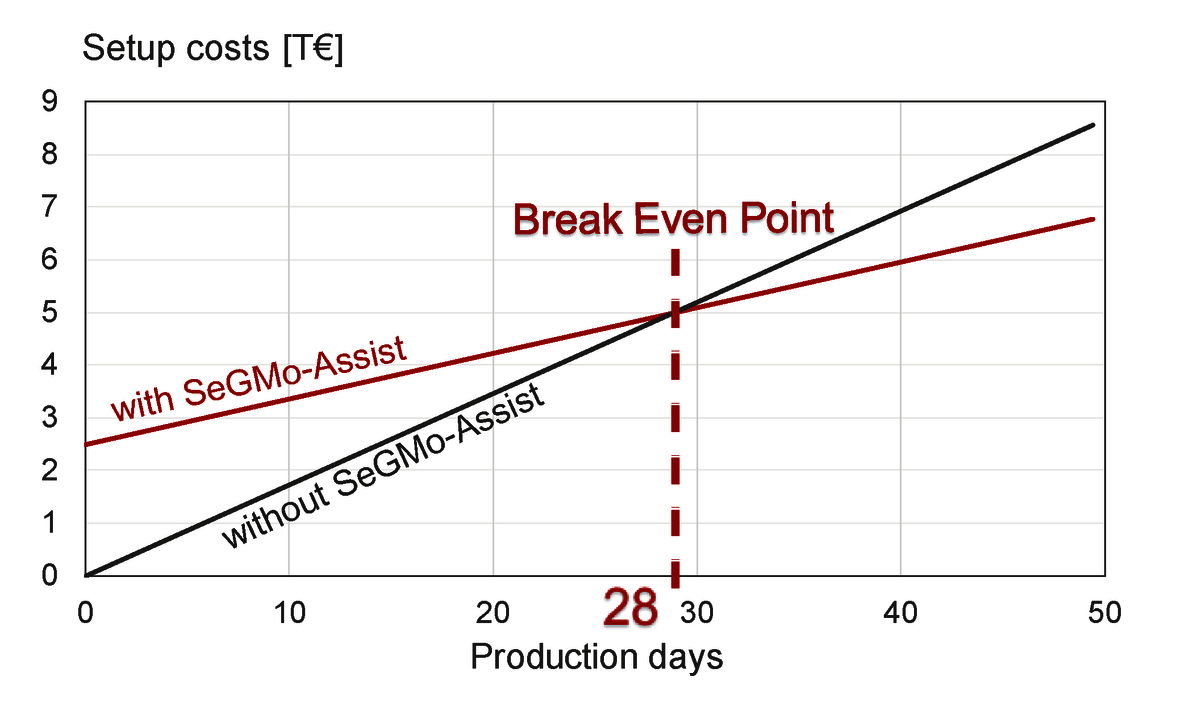

SeGMo-Assist helps you digitize manual format adjustments. Achieve high savings in the production process with little outlay! Your investment usually pays for itself within one month.

You also save costs during operation, as the position display SeGMo-Assist doesn’t require a backup battery. Maintenance and service costs are thus a thing of the past. We will be happy to calculate your potential savings!

Easy monitoring of your application

Do you use in-house programming for your condition monitoring? This not only puts a strain on your human resources, but also on the capacities of your PLC. This is because very large data streams have to be collected, analyzed, processed and visualized online for permanent plant monitoring, thus reducing the reaction speed of your machinery. But this doesn’t have to be the case! Condition monitoring with the modular SeGMo-Box solves these capacity issues:

- Complete overview in real time: Positioning drives are permanently monitored

- Safety: A web server provides a separate communication channel for Industry 4.0 applications and remote maintenance

- System-independent: Easy integration into your control system

- Convenient analysis thanks to visualized and processed condition data

All system data of the positioning drives are provided in the web server. Optional software packages help you to visualize them:

- Intuitive evaluation thanks to traffic light system and prepared graphics

- Easily monitor individual applications: Compare current data with past data in torque analysis, for example

Lack of space is a thing of the past

You’d like to increase the efficiency of your production line with automatic positioning systems, but you only have limited installation space available? SeGMo GEL 6129 compact positioning drive solves this problem. It allows you to make automatic machine adjustments to different formats despite limited space in your system.

Your advantages:

- More design freedom due to a range of connection options (straight and angled connectors) and small dimensions

- Easy system integration: identical housing dimensions for all variants (2.5 Nm and 5 Nm)

- Low life cycle costs and maintenance-free thanks to a batteryless absolute rotary encoder

You too can rely on fast, reproducible changeovers! Also take advantage of potential savings – this is now even easier with the GEL 6129 in its robust plastic housing. Standalone use with integrated fieldbus module also gives you cost advantages.