Renewable energy Reliable and innovative system solutions

Modern wind turbines defy subtropical heat and Arctic cold as well as dust, sand and dirt. In offshore wind farms they are exposed to high levels of humidity and salt mist. All components must also be able to withstand the vibrations of the nacelle. And they need to do all this round the clock, 365 days a year. Reliability is essential if expensive and time-consuming maintenance is to be avoided.

Our robust controllers and sensors will ensure the safe operation of your wind turbine and continuous online condition monitoring. More than 50,000 of our PitchControllers are in reliable use across the world. Why not profit from our innovative system solutions and many years of experience?

i³SAAC

We have given a name to futuristic innovations: i³SAAC. As an experienced pioneer in the wind energy sector, we have been able to set trends early. We and our customers were focusing on the availability of system data in the control room many years ago, for instance. Today’s and tomorrow's requirements in terms of network stabilisation, remote diagnosis and maintenance, etc., need further leaps in innovation.

That is why our aim is to make your wind turbines more and more transparent, efficient and reliable. With our intelligent, integrated and interactive (i³) sensors, actuators and autonomous controllers we ensure highly efficient applications. Tell us what your future requirements are, and together we will develop efficient and resilient solutions to meet your challenge.

Efficient control of the rotor blade position

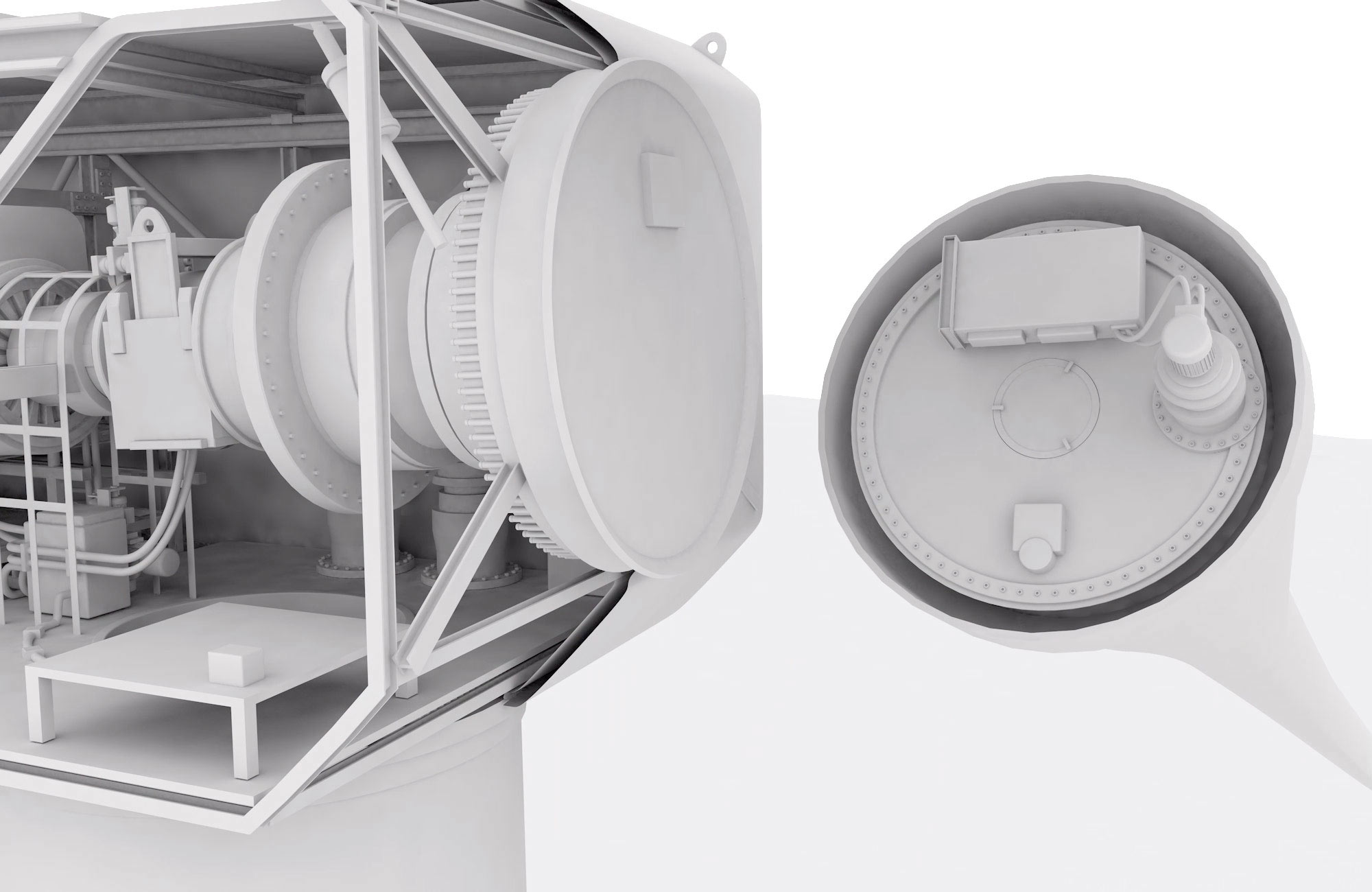

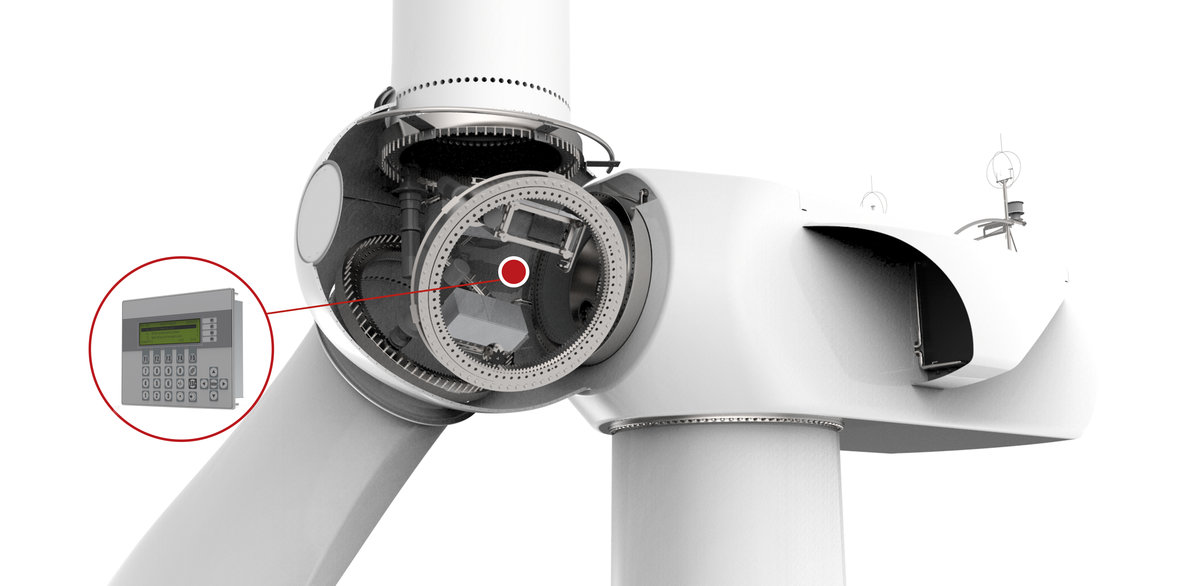

You want to achieve the maximum energy yield from your wind turbines. That's why precise, reliable positioning of the rotor blades is particularly important if pitch speed is to be optimised. Put your trust in our compact control systems, which have proven themselves in this demanding application.

The latest, enhanced generation combines decades of experience with a significant improvement in performance. The PitchControllers GEL 8400 are optimised for the tough environmental conditions in the rotor hub. Even extreme temperatures of -40° C to +85 °C won’t faze them!

The integrated display makes it easy for your service engineers to operate directly in the hub. The plant parameters can be adjusted on site with a guided menu. Our service tools for reading and writing the parameters significantly simplify commissioning and maintenance. Firmware updates can be run from the control room without dismantling the device. All relevant system parameters are recorded, transmitted and visualised, allowing you to monitor the condition of your plant.

Speed and position acquisition in the pitch system

Optimise the energy yield of your wind turbines by aligning the rotor blades precisely. Acquire the blade position with our robust, high-resolution sensors. The magnetic measuring system is more than a match for extreme ambient temperatures, humidity, dirt, condensation and strong vibrations.

We recommend our absolute rotary encoders GEL 2037with integrated bearings and heavy-duty flange or target wheel adapter. The redundant measuring system with integrated electrically isolated resolver and 25-bit resolution is ideally suited for this application. The gear-based multiturn encoders acquire changes in the blade position safely and reliably. The benefit to you is that the battery-less sensors operate maintenance-free.

Do you have little available installation space in the pitch motor? Then why not use our much smaller incremental speed sensors GEL 248? They allow a target wheel connected to the motor shaft to be scanned contactlessly, which means they do not wear out and require no maintenance. By using two sensors on one target wheel, we can create a redundant system for you.

Accessible from anywhere in the world

Integrate our controller easily into your control system using standard interfaces. The remote service web means you can access it from anywhere in the world. The web browser allows you to monitor the condition of the current actual values and read and write parameters. The remote service logbook permanently records every access to the system, which means you always have an eye on the control of your pitch system.

Individual support

Can’t find a suitable product for your application? Our technical support team will be happy to advise you. Contact us now!

*Mandatory fields

Your contact

Frank Mertens, Key Account Manager