Sensors for wheel slide protection

Modern brake management distributes the braking force optimally over the different brake systems throughout the train. The frictionless interplay of the components involved is an essential selection criterion for vehicle manufacturers and operating companies. To guarantee a uniform standard in railway rolling stock, the worldwide railway organisation UIC (Union internationale des chemins de fer) based in Paris tests and certifies such safety-related systems and components. One example of these are incremental encoders as part of wheel slide protection equipment. With the approval of speed sensors for various wheel slide protection systems, Lenord + Bauer offers its customers greater safety when selecting suitable components. The sensors of the GEL 2475 and 2476 series with brake system-related output signals have been approved by the UIC for the MGS 1, MGS 2, WGMC 19 and MRP-GMC 29 wheel slide protection devices.

Wheel slide protection systems are intended to prevent the blocking of wheel sets during the braking process. Wheel slide protection devices evaluate the rotational speeds of the individual vehicle axles for exact brake control. Rather like ABS systems in cars, they individually control the braking force on every single axle, thereby preventing the formation of flats on the tyre. For wheel slide protection, the standstill of the wheels must be detected reliably. Sensors with a current output or delivering a stalled torque are particularly suitable for this purpose. When the axle is at a standstill, sensors with a current output deliver a low level of 6 mA. In this case the output level of sensors with a stalled torque stands at 7 V. This allows the wheel slide protection system to recognise that the wheels have come to a stop and to distinguish this from the possible failure of the measuring system.

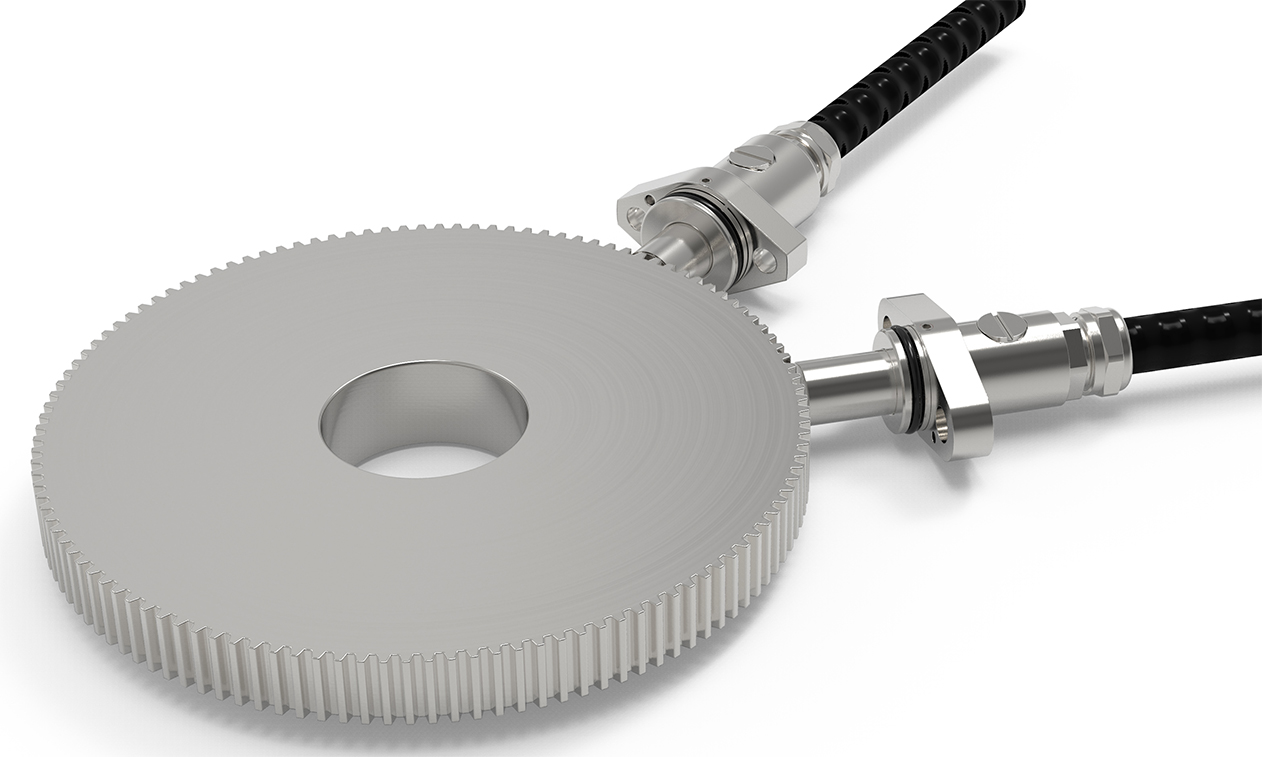

With a frequency range of 0 to 8 kHz, the sensors are specifically tailored for use with wheel slide protection devices. The sensors are available with one channel or two electrically isolated channels. The GEL 2475 and 2476 variants differ in their flange form and the diameter of the sensor tube. The hole pattern conforms to the standard in the railway industry. Special encapsulation enables them to withstand temperature differences, shocks, humidity and vibration. All wheel slide protection sensors of the Oberhausen-based company meet the requirements of DIN EN 50155 and offer IP 67 degree of protection.