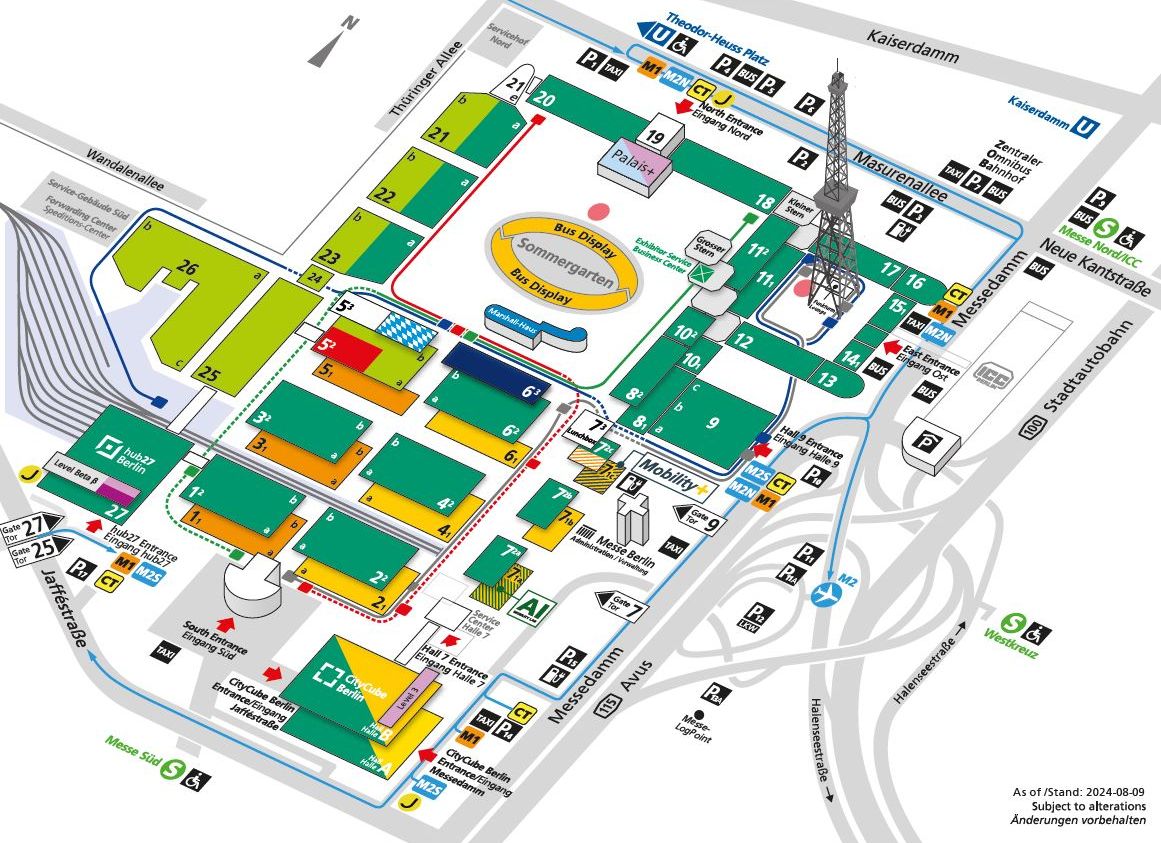

Discover our sensor highlights Visit us at InnoTrans 2024!

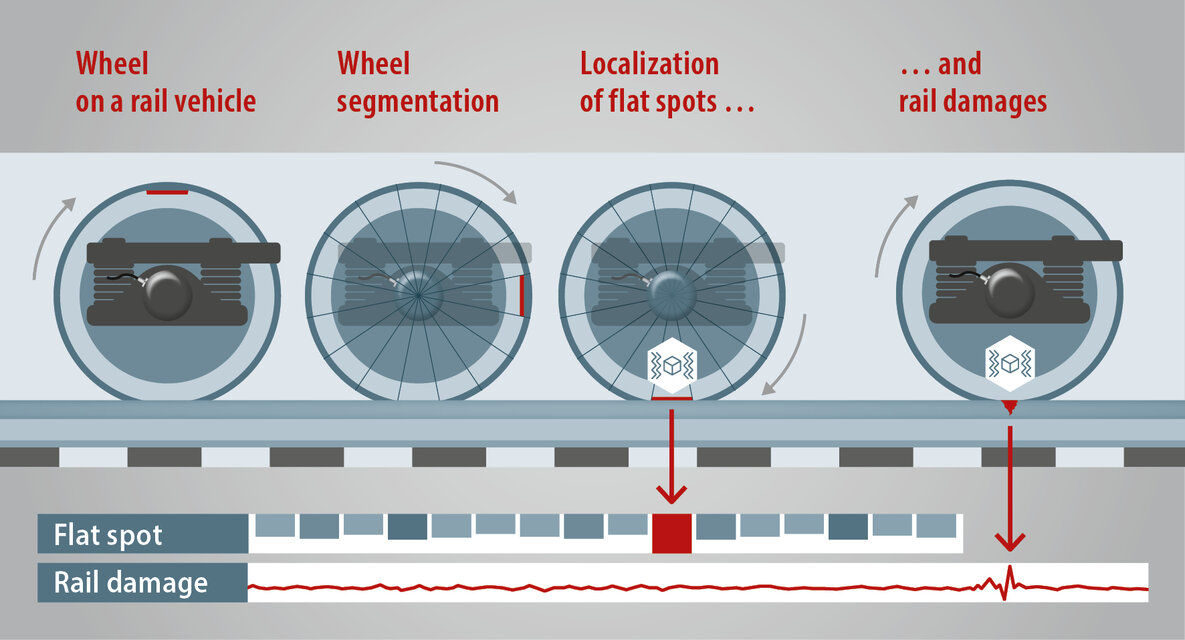

Detection of flat spots on rail vehicles

Undetected flat spots, welds or crumbling on the wheel tire can lead to serious consequential damage and have an impact on ride safety. The GEL 2475FD flat spot detector has integrated detection of periodic impact loads. This allows flat spots on the wheel tires to be reliably detected, classified and located and clearly distinguished from damage to the rail infrastructure. Noise emissions can be efficiently reduced through targeted maintenance measures.

Your advantages:

- Automatic, objective detection and evaluation of flat spots and rail damages

- 1:1 replacement for existing odometer pulse generators possible

- Early warning can help to reduce wear and tear and workshop times

- Reduction of noise emissions in urban environments

Acquisition of rotational speed, vibration, and temperature

If the installation space is limited, our CombiCODER combines several sensor types in a single housing. Our new GEL 2475CM simultaneously measures rotational speed, temperature and vibrations. It detects vibrations in up to 3 axes with 2.4 kHz bandwidth. Instead of mounting three to four sensors, you only have to mount and test one sensor. This significantly reduces the time required for assembly.

Your advantages:

- Perfectly suited for Condition Monitoring of gears

- Integrated speed signals to determine the expected fundamental frequencies

- Developed and tested in accordance with EN 50155

Rely on our expertise in original equipment and retrofitting and talk to us about your projects at InnoTrans!