Cost-efficient drive for a broad range of automation applications

To complement positioning drives with degree of protection IP67, Lenord+Bauer now offers a solution for applications where IP 54 is sufficient. The compact design, which has proven a successful commercial feature, has been retained. The batteryless absolute rotary encoder, which is installed in all SeGMo products, is also a feature of the new drive. Maintenance-free electrical parts guarantee a high degree of reliability and low life cycle costs. Battery replacements and unscheduled machine downtimes resulting from that are now a thing of the past.

The GEL 6009 unit is equipped with a flexible 14 mm semi-hollow shaft, which can be adapted to smaller diameters using reducing sleeves. This increases the number of identical parts, improves uptimes and simplifies storage options for the machine manufacturer.

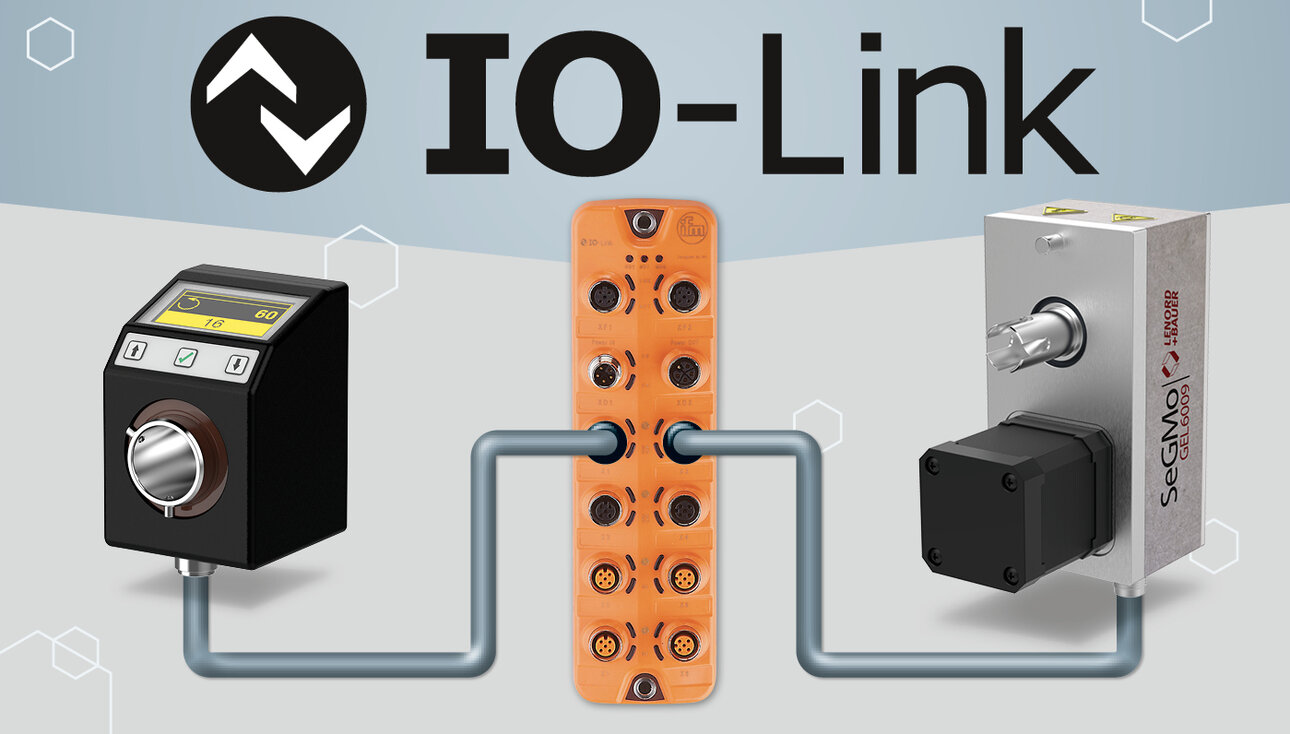

By supporting the simple IO-Link cable topology, there are advantages when using the new drive in combination with the company’s digital position indicators. Both the SeGMo-Assist displays and the GEL 6009 can each be operated on an IO-Link master using a single cable. This simplifies planning of systems, as only the terminal device has to be selected according to the desired degree of automation. The existing IO-Link hardware, that is the IO-Link master and cabling, remains unchanged. In future, the GEL 6009 will also be available with integrated Industrial Ethernet fieldbus interfaces.