Innovative sensor technology for spindle applications and machine tools Visit us at AMB! See you at stand 7-C71!

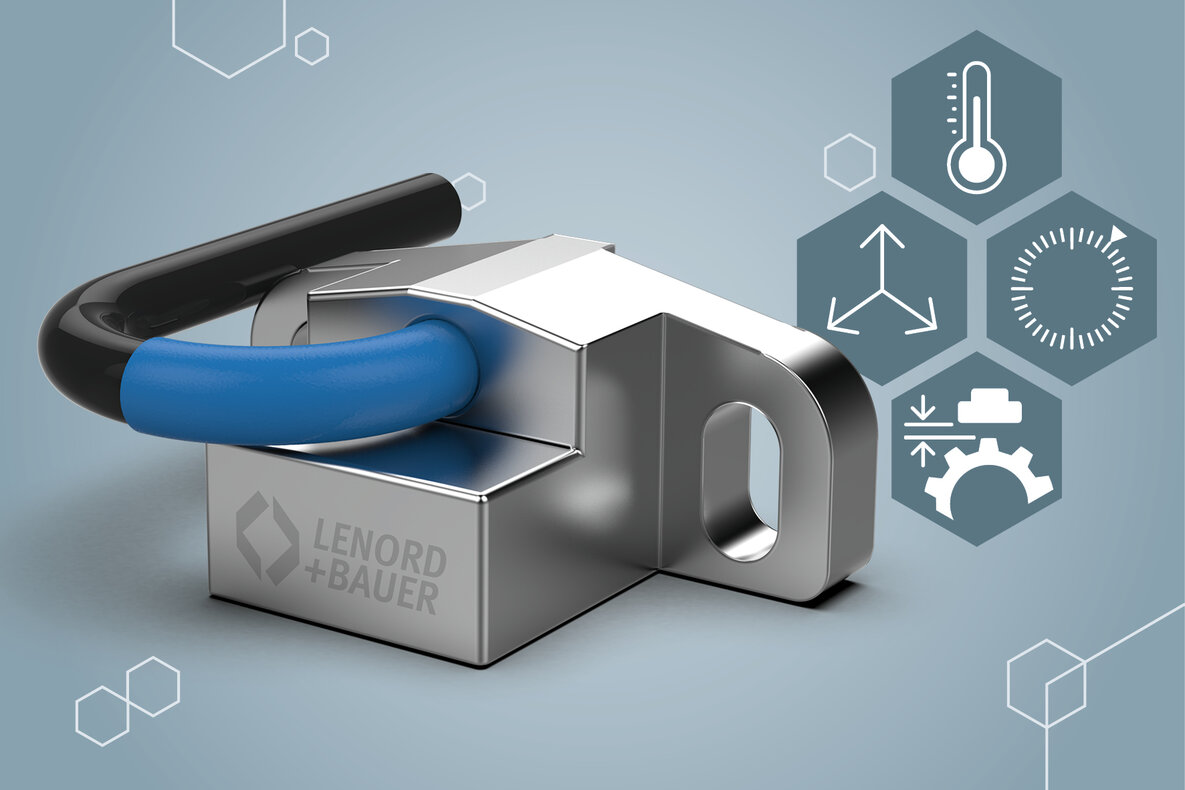

Smart condition monitoring sensor for spindle monitoring

How can you avoid machine downtimes and save on costs? The MiniOBSERVER records process-relevant parameters including vibrations, temperature and shaft displacement directly on the tool spindle and evaluates these parameters in relation to speed and position. This means that critical system events can be detected at an early stage thus preventing downtimes.

We will be happy to tell you more at the stand of our cooperation partner Mitsubishi Electric in Hall 7, Stand C 71. Make an appointment now!

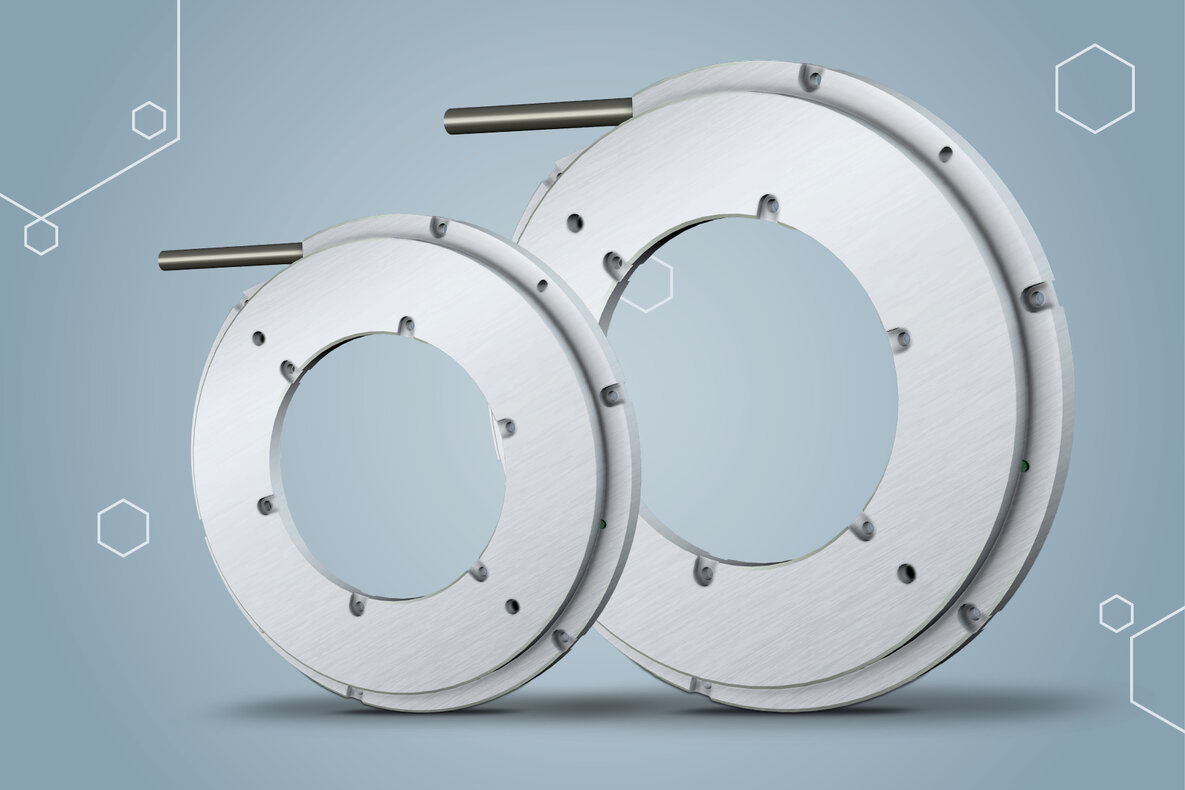

Singleturn encoder kit for dynamic and precise positioning

Dynamic control at speeds up to 30,000 rpm? Precise positioning with accuracy of up to 5 arcseconds? With our new absolute sensor system, we offer you a mechanically robust and, thanks to the inductive sensing principle, a wear-free and maintenance-free solution for a wide range of high-speed and positioning applications.

The flexible design with different diameter variants and mounting methods simplifies integration into applications with large hollow shafts in particular.

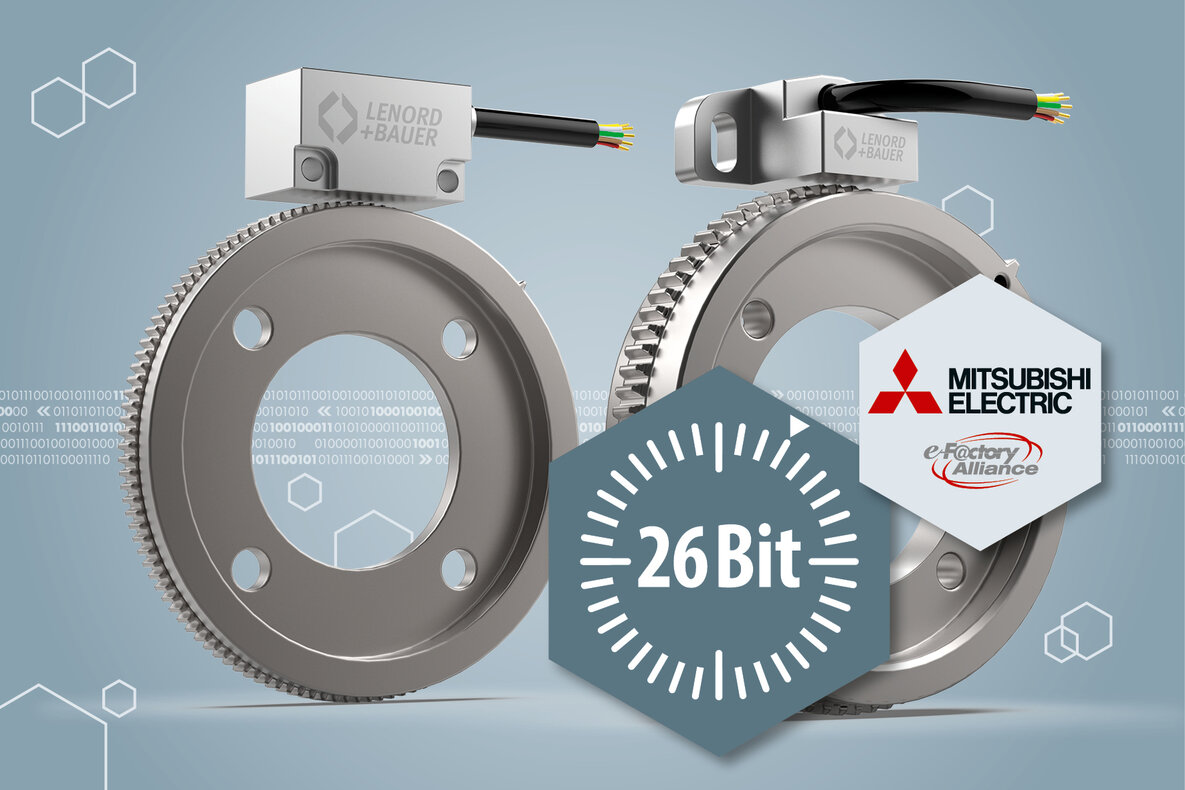

High-resolution digital encoder kit with Mitsubishi interface

In addition to increased resolution of up to 26 bits, the new generation of digital MiniCODERs offers some exciting new features, such as intelligent warning and error messages or integrated installation analysis. The redesigned web app for the SensorDEVICE M mobile service unit now provides even more convenient support for sensor system installation and servicing.

Trust in our expertise as market leader. Let’s talk about your projects at AMB!